iso hardness testing standards|astm standards for hardness testing : traders For instance, material testing standards like ISO 148-1 (Charpy impact testing) and ISO 6508 (Rockwell hardness testing) allow industries to have reliable methods to assess material toughness and hardness. The application of these standards is a necessity in sectors where failures of materials can have catastrophic consequences. It is a Class N autoclave with complete leak proof chamber and a timer range of 0 ~ 60 min .With fast heating capabilities, this portable autoclave reaches high temperatures .

{plog:ftitle_list}

The necessity of qualifying an autoclave and validating the sterilization process arises from various laws and regulations. Although the terms qualification and validation are usually mentioned in one sentence or even used .

International Standard 6508-1 was prepared by the Technical Committee ISO/TC 164, Mechanical testing of metals, Subcommittee SC 3, Hardness testing. This first edition of ISO 6508-1 cancels and replaces ISO 6508:1986 and ISO 1024:1989, of which it constitutes a technical revision as .ISO 6508-1:2015 specifies the method for Rockwell regular and Rockwell superficial hardness .The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .If a testing machine is also to be used for other methods of hardness testing, it shall be verified independently for each method. ISO 6507-2:2018 is also applicable to portable hardness testing machines but not applicable to hardness testing machines based on different measurement principles, e.g. ultrasonic impedance method.

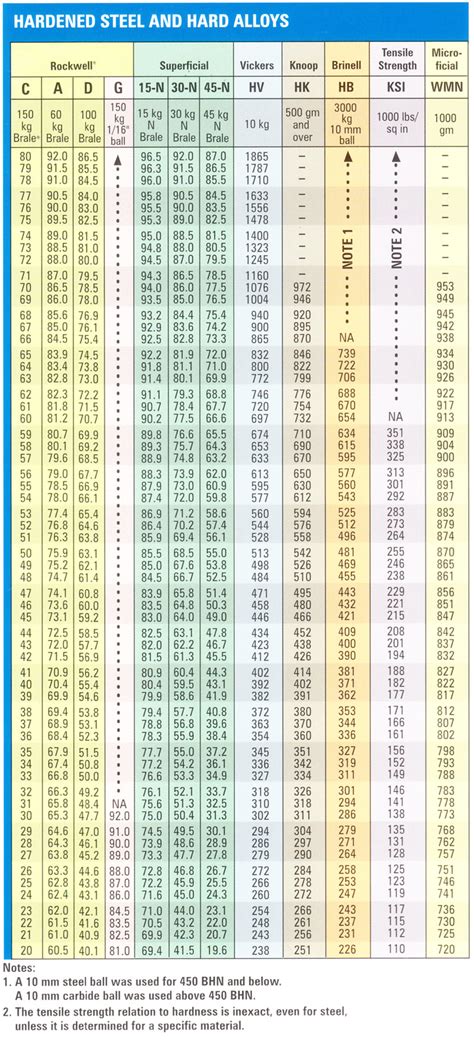

rockwell hardness testing chart

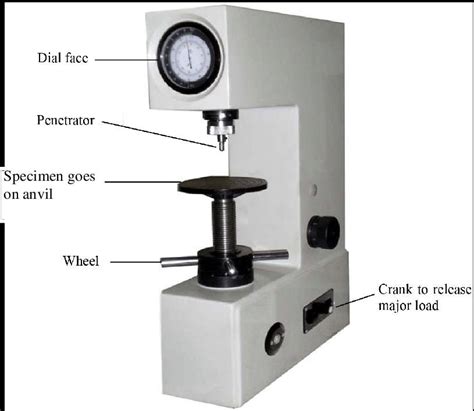

rockwell hardness tester diagram

For instance, material testing standards like ISO 148-1 (Charpy impact testing) and ISO 6508 (Rockwell hardness testing) allow industries to have reliable methods to assess material toughness and hardness. The application of these standards is a necessity in sectors where failures of materials can have catastrophic consequences.of film hardness by pencil test Peintures et vernis — Détermination de la dureté du feuil par l'essai de dureté crayon INTERNATIONAL STANDARD ISO 15184 Third edition . Paints and varnishes — Standard panels for testing ISO 2808, Paints and varnishes — Determination of film thickness ISO 4618, Paints and varnishes — Terms and .ASTM E140 Standard Hardness Conversion Tables for Metals Relationship among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Harness, Knoop Hardness, and Scleroscope Hardness. 2 Principles of conversion Hardness testing is a form of materials testing that provides information on the mechanical properties

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO member bodies). The work of preparing International Standards is normally carried out through ISO technical committees. . ISO 6508-1:2015, Metallic materials — Rockwell hardness test — Part 1: Test method; ISO 6508-3:2015, .

ISO/TS 19278 standard enables precise hardness testing of plastics, even for thin or small specimens, using the DUH-210 tester. . Under the ISO/TS 19278:2019 standard, a hardness tester conforming to ISO 14577-1 (Metallic Materials – Instrumented indentation test for hardness and materials parameters – Part 1: Test method) is needed. .ISO 6508-2, Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines and indenters ISO 6508-3, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Terms and definitions No terms and definitions are listed in this document. ISO and IEC maintain terminology .If a testing machine is also to be used for other methods of hardness testing, it shall be verified independently for each method. This document is also applicable to portable hardness testing machines but not applicable to hardness testing machines based on different measurement principles, e.g. ultrasonic impedance method. 2 Normative references

abcam p24 elisa kit

iso 6508 PDF free download

abcam pge2 elisa kit

The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring-loaded indenter made of hardened steel to indent the material/specimen.The indentation depth is a measurement for Shore hardness, that is .Metallic materials — Rockwell hardness test — Part 1: Test method. Skip to main content. Applications . For specific materials and/or products, other specific International Standards apply (e.g. ISO 3738-1 and ISO 4498). General information. Status : Published. Publication date : 2023-12. Stage: International Standard publishedISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO member bodies). The work of preparing International Standards is normally carried out through ISO technical committees. . [11] ASTM E18, Standard Test Methods for Rockwell Hardness of Metallic Materials [12] ISO 18265, Metallic . For specific materials and/or products, other specific International Standards apply (for instance, ISO 3738-1 and ISO 4498). . This International Standard specifies methods of hardness testing of sintered metal materials, excluding hardmetals. Procedure 1 determines the apparent hardness of the whole material. Procedure 1 —.

Metallic materials — Vickers hardness test — Part 1: Test method. . The Vickers hardness test is specified in ISO 6507-1:2005 for lengths of indentation diagonals between 0,020 mm and 1,400 mm. General information. Status : Withdrawn. Publication date : 2005-12. Stage: Withdrawal of International Standard Edition : 3. Number of pages .

ISO 18517:2015(E) 3.2 standard hardness S hardness, in international rubber hardness degrees, obtained using the procedures described in ISO 48 on test pieces of the standard thickness and not less than the minimum lateral dimensions specified 3.3 apparent hardnesshardness standards (E384 microindentation & E92 heavy-load Vickers), and consolidating them into a single document. As the Head of Delegation for the US delegation to the ISO hardness committee, NIST is leading the revision of the ISO Rockwell hardness standard (ISO 6508). Currently, NIST produces hardness test blocks as SRMs for a variety of .The ISO 898-1, ISO 3506-1 and ASTM F606 standards describe tests on threaded fasteners (bolts, screws and studs) including steel screws and their mechanical and physical properties such as tensile strength, offset yield (minimum stress), elongation after fracture and hardness.. ISO 898-1 establishes the mechanical properties of fasteners made of carbon steel and alloy .

ISO 6508-2:2015, Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Principle An indenter of specified size, shape, and material is forced into the surface of a test specimen under twostandard hardness value indicated on a test block must be obtained by testing it under general testing conditions. In contrast, the loading conditions prescribed in the ISO test block standards for Brinell and Vickers hardness tend to deviate from the standard conditions specified in the test method standards. This tendency seems to suggest someThis is a multi-part document divided into the following parts: Part 1 Metallic materials.Vickers hardness test. Test method; Part 2 Metallic materials.Vickers hardness test. Verification of testing machines

hardness tester drawing

STANDARD ISO 16859-1 First edition 2015-09-15 Reference number . SC 3, Hardness testing. ISO 16859 consists of the following parts, under the general title Metallic materials — Leeb hardness test: — Part 1: Test method — Part 2: Verification and calibration of the testing devices

Hardness testing standards have been set by various organisations such as The American Society for Testing and Materials (ASTM) and The International Organisation for Standardisation (ISO), prescribing specific varieties of a hardness test determined by factors such as the type of indenter, applied force, and procedure of force application.

Material testing standards, including ISO standards, provide guidelines and specifications used to assess the mechanical properties of materials. These standards are critical for ensuring consistency and reliability in material usage and testing methodologies across various industries. . yield strength, hardness, and bending ability. ISO 898 .

Standards: EN ISO 6507 / ASTM E18 Rockwell Methods 1.2.ISO 48-2 also specifies modified procedures for use on curved test pieces, with the result being expressed as apparent hardness. A dead-load method for very soft materials using the very low rubber hardness scale (VLRH) is specifiedISO 6506-1:2014 specifies the method for the Brinell hardness test for metallic materials. It is applicable to both fixed location and portable hardness testing machines. For some specific materials and/or products, particular International Standards exist (e.g. ISO 4498) and make reference to this International Standard.

1.5 Units— At the time the Rockwell hardness test was developed, the force levels were specified in units of kilograms-force (kgf) and the indenter ball diameters were specified in units of inches (in.). This standard specifies the units of force and length in the International System of Units (SI); that is, force in Newtons (N) and length in millimeters (mm).

abcam rhk 324-01r myeloperoxidase mpo elisa kit 96w

Autoclaving (wet 121°C, 15PSI for 30 minutes)–Before autoclaving, verify that the caps are properly loosened or removed to prevent any accidental .

iso hardness testing standards|astm standards for hardness testing